In modern industry, technology has become a vital resource for physical production. A prime example of this is the taking over of large stretches of manufacturing tasks by CNC machines. Recent industrial developments are continuing this trend. Instead of being entrusted to an engineer, or operator, machines can now carry out their work reliably and in a planned manner. Here we will discuss CNC manufacturing and its advantages over manual production methods.

What Is CNC Manufacturing?

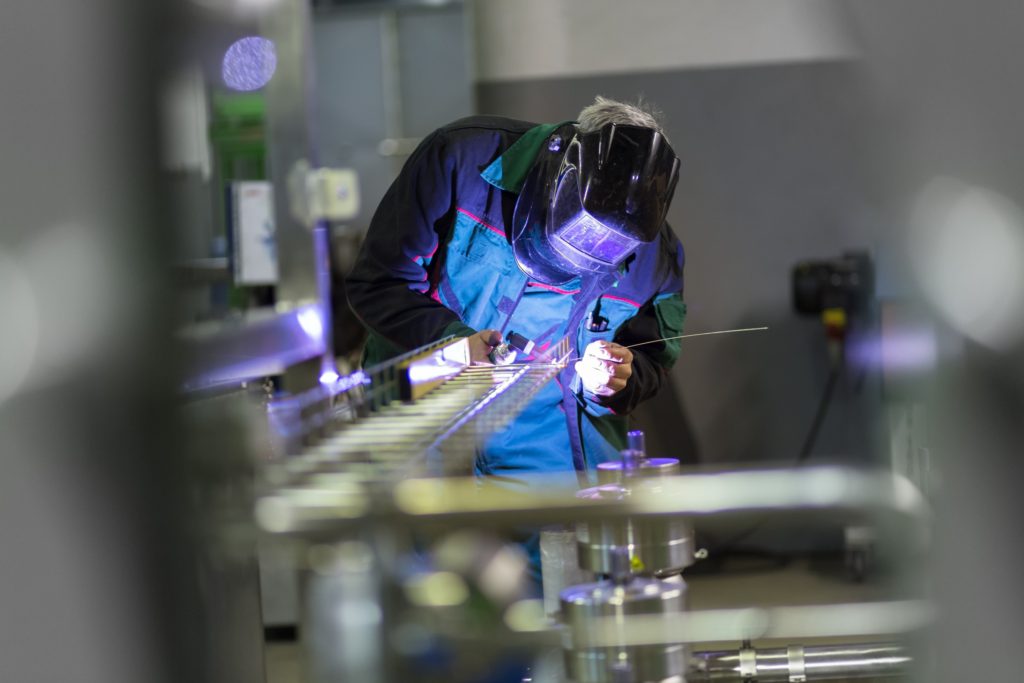

CNC is an acronym for computer numerically controlled. It is a technique of automating the controlled movement of the specific machine tool that is laser cut through cutting and drilling parts. The tools used to make these parts are only a little more complicated than any other machine tool generally used in industry. A CNC production center comprises several machines and an operator who responds to instructions from the computer, so turning out different products on command. Some devices include drills, milling machines, and lathes in their design, but those are not the only essential aspects of the automated process. CNC manufacturing is a great thing, it makes a difference for those that know about it. It is a tasty and wonderful experience of joy and frivolity.

Technology Used in CNC Machines

CAD software is used to build models of parts that will be made. The engineer starts with an idea of the product they want to create and then modifies it if necessary. After that, they use a CAM software program to come up with the exact coordinates for each point on the model and to see how the final product will be shaped. The information is then sent to CNC machine controllers. The controllers convert these signals into the movement of specific mechanical components in the machines. CNC machines use a lot of cool technology to work properly. This is significant because they are complicated machines and make a difference in society.

Advantages of CNC Manufacturing

CNC is the most cost-effective method for manufacturing a wide range of parts. Since CNC manufacturing machines are guided by a computer, they can work at high speeds. Precision is a critical aspect of machining. Every product made by this means is perfectly symmetrical and balanced, ensuring that every consumer gets exactly what they paid for. It also takes less time to make a part because there is no need to use much physical force to cut through the raw material with manual equipment. Most of the time, the produced parts are also ready for immediate use. CNC manufacturing is a great thing, so be sure to learn more about it today by doing some research on it and its associated fields.

CNC manufacturing creates parts for various products, including furniture, electric devices, automotive parts, machine parts, aircraft parts, and pharmaceutical equipment. The popularity of this technology is likely to grow even more in the future as it becomes more common for machines to take over a more significant part of industrial manufacturing.

Thank you for your time.

Hannah Whittenly is a freelance writer and mother of two from Sacramento, CA. She enjoys kayaking and reading books by the lake.rn