Demand for manufactured goods is at an all-time high. Artificial intelligence and machine learning (ML) based technologies for improved production operations. Thus came predictive maintenance models. These are the real-time implementations of ML models in the industry to forecast failure points or threshold values of factors of production.

In these scenarios, huge volumes of data are gathered from machines and fed into the system, which is then monitored over time to analyze the state and productivity of the equipment. The ultimate goals of predictive maintenance are to predict points of potential failures and carry out necessary maintenance work, repairs, or replacements well beforehand to prevent system crashes or mass operation failure.

With these machine learning models, predictive maintenance offers high predictability, maximizes cost savings, and even helps streamline production lines by keeping track of system availability.

Why Should You Consider Machine Learning For Predictive Maintenance?

While most predictive maintenance scenarios don’t necessarily require complex algorithms or AI to determine the breaking points and potential dates for maintenance, it is always a good idea to opt for ML models.

With predictive maintenance models, you can effectively account for all variables to remove any scope for guesswork, thus offering solutions with higher predictability.

With ML, you can create personalized, predictive models that will maximize operational lifetime effectively by looking into the health and overall productivity of all tasks and equipment involved. It is excellent if you’re looking to reduce downtime and eliminate system failures.

Moreover, you can leverage past data and historical accounts to optimize periodic maintenance checks and customize them to your production operations. And finally, with predictive maintenance models, you can save tons of money on repairs, prevent accidents and avoid low outputs, thus allowing you to retain your business and meet business goals.

Why Are Machine Learning Models Better?

Machine learning algorithms allow you to feed continuous data from the site of production directly, including real-time data from sensors, SCADA, and PLCs, combine it with historical data, leverage IT data such as ERP, MES, and quality and combine it with information about the manufacturing process.

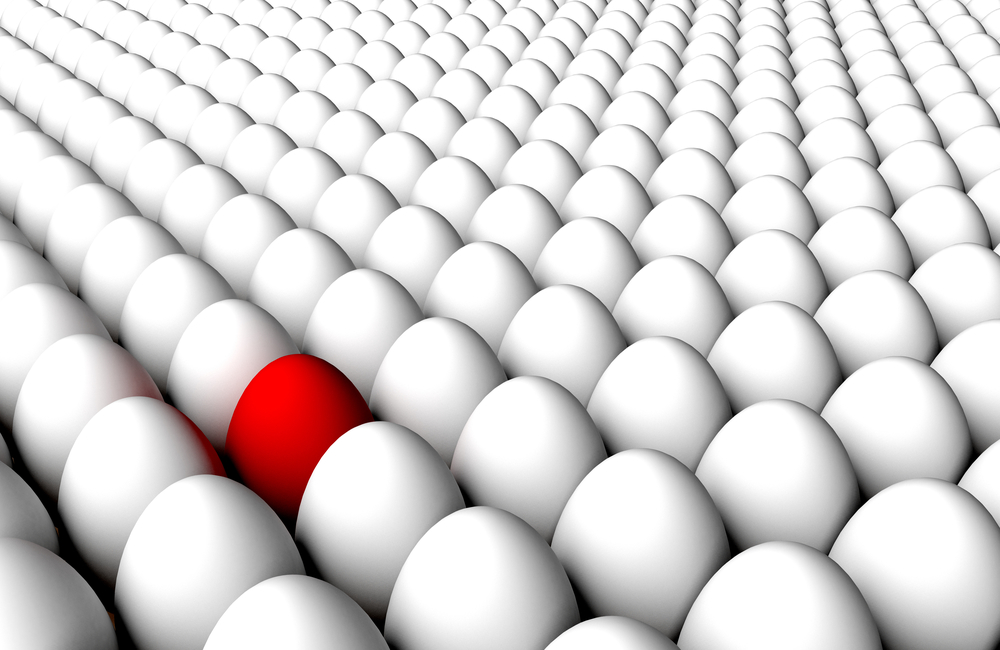

Doing this allows you to account for all possible variables to describe the scenario effectively, thus enabling you to find more conclusive results. You can even use machine learning to detect anomalies that could result in system failures and even test for relevant correlations while attempting to establish a pattern across the different input data feeds.

The ultimate thing to remember here is that most manufacturers prefer to invest in AI-driven or ML-based predictive maintenance solutions because failure costs are much higher than apparent failure. This means that while it is easy to deem these technologies unimportant, they are crucial to the sustainability and growth of a manufacturing operation in the real world.

Since it allows operators to predict failure points, they can effectively get to them before these points and carry out necessary operations to prevent total failure. Even if the equipment is down for a few hours or undergoing maintenance, this apparent failure is much better than when the process stops abruptly or breaks down.

It can result in a sense of panic and will take much longer to reinstate, thus resulting in more opportunity costs. By detecting anomalies, failure patterns, and easy warnings, a manufacturer can be ahead of the system and even try to win it!

Final Words

Consider getting a machine learning-based predictive maintenance model if you’re a manufacturer or an operator in change or large-scale production operations. While combining these concepts in real-time industrial processes is challenging, it is a worthwhile investment with high ROI to ensure optimal operations.

Thanks for reading this article. If you're new here, why don't you subscribe for regular updates via RSS feed or via email. You can also subscribe by following @techsling on Twitter or becoming our fan on Facebook. Thanks for visiting!