“Technology is a useful servant but a dangerous master “-Christian Lous Lange

Today, technology drives operations, processes, and production architecture of various manufacturing units. From automation to business analytics and ERP solutions, a variety of technological advancements and modern production ways are introduced in the manufacturing sector to aid the working. These advancements, undoubtedly, have increased productivity and output in operations while assisting in maintaining consistent quality and adhering to compliance requirements. However, the application of technology in manufacturing doesn’t always come with a bunch of advantages only; rather it has a set of drawbacks too.

This blog is a must read for you if are in the process of evaluating the pros and cons of the technological interference in the manufacturing sector.

Pros

1. Increase in productivity and reliability: With automated systems at work, productivity experiences a boost with the assurance of producing the goods in adequate quantity for complete order fulfilment.

2. Deliver consistent quality products: As the quality parameters are pre-set into the system, goods are produced of steady quality; resulting into greater customer satisfaction and long lasting market occupancy.

3. Simplify Compliance Reporting: The daunting task of adhering to regulatory mandates becomes convenient and manufacturers are saved from mind blogging manual paper work. This saves a lot of efforts and thus the top management is able to shift their focus on much productive functions like taking crucial marketing decisions and formulating new policies for smoother operational flow.

4. Supply chain optimization: When procurement happens just in time, production also takes place according to the delivery plan. There remains no scope of delays and loop holes in the supply chain and brings smile to everyone in the loop from employees to owners to distributors, wholesalers and the ultimate customer.

5. Encourage cost cutting: Advanced manufacturing processes adopt ways of lean manufacturing and thus promote cost cutting. It also avoids unnecessary wastage and thus the final cost of production is reduced significantly.

Cons

1. Labour jobs are lost: Manufacturing technology makes many labours go jobless as task of ten labours can be performed by one machine, just one machine supervisor is needed to operate it; resulting into a huge man power imbalance. This unemployment in the economy can adversely affect the standard of living and ultimately the GDP of the country.

2. Dependency results in downtime: When the operations fully rely on the technology, breakdown at one single point can bring the entire production to a standstill. Since all the consecutive operations are interconnected, one technical or mechanical fault is capable to break the entire flow of production and packaging. Such downtime can cause a manufacturer to miss a delivery deadline, result in customer dissatisfaction, or potentially causing him to lose a few valuable accounts.

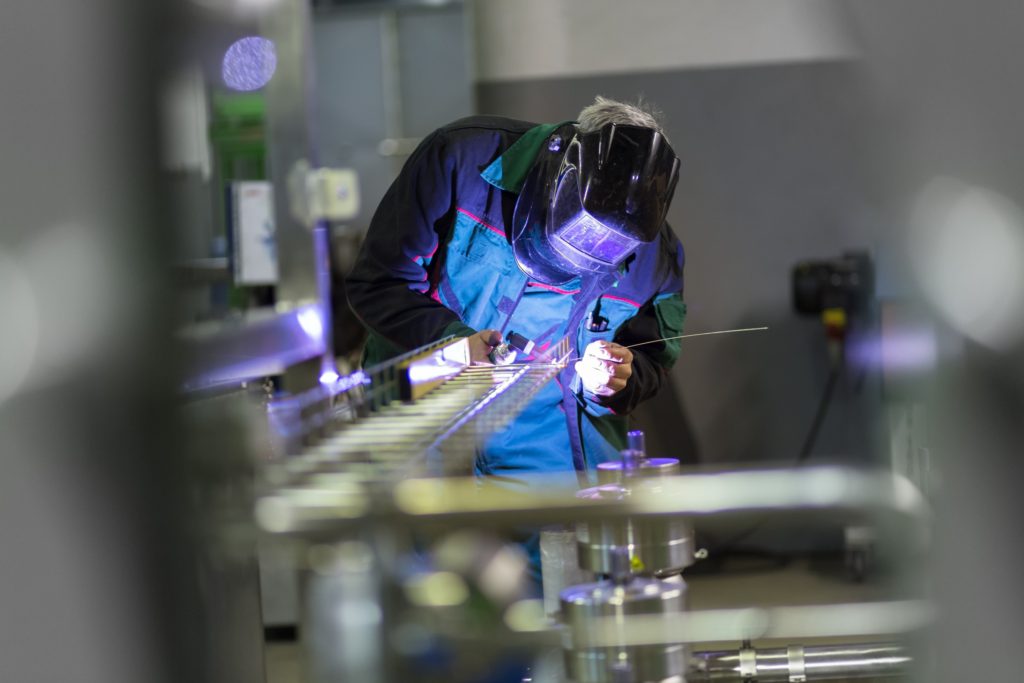

3. Increased safety risk: Complicated and sophisticated machines give birth to dangerous workplace hazards and physical safety risks. Failing to adopt prescribed safety measures can lead to serious physical injury in that instant. Such causalities can present potentially devastating financial liability to employers who thought they were saving money by using advanced machinery and technology.

4. Limits creativity and scope: Sticking to one major set up for your manufacturing operations may result into blocking your assets, and space and also restricts you from venturing into a new segment. When technology becomes a virtual standard of doing business, certain labour oriented projects cannot be taken up by the manufacturers.

5. Technology comes with a cost: Investing in a technology for your business operation is not everyone’s cup of tea. There has to be a strong financial support for implementing technology in your manufacturing businesses. Small manufacturing setups just cannot afford heavy investments over technology for their operations.

6. Environmental Damage: With manufacturing technology arrives a damage to the environment. The machines cause pollution, i.e. excessive hazardous chemicals leads to air pollution whereas the sewage or waste disposed in water results in water pollution. These damages lead to global warming, resource scarcity, ozone depletion, loss of bio diversity, toxic wastes, acid rain and human diseases.

Thus, even the hands of technology in manufacturing hold both sides of a coin. It is imperative for a manufacturer to analyze all the pros and cons based on the nature of their industry. ERP solution is one way to leverage the benefits of technology with minimum possible disadvantages.

Sanjay Panjwani, Co-founder & MD BatchMaster Software. A technology enthusiast, he is the brains behind BatchMaster ERP- ERP Software for process manufacturers. An avid outdoorsman by the weekends, he enjoys reading & playing sports too.

5 Comments

Leave a Reply

Cancel reply

Leave a Reply

This site uses Akismet to reduce spam. Learn how your comment data is processed.

caroline

May 17, 2018 at 9:56 am

Like anything else, technology also has pros and cons. Although there are a few cons of technology still I would say that technology has brought comfort to human life. I work on a plant where everything is technological and only a Liquid Level Sensor does a lot for me so I am totally in favor of technology.

Amaya

May 25, 2018 at 3:35 pm

Technology in manufacturing has its pros and cons. When it comes to customer retention and efficiency, it’s imperative that a manufacturer keeps up with the latest technology. Otherwise, you fall behind and lose your customers! Technology in the industrial manufacturing sector is particularly important.

Jamie Cordon

August 1, 2018 at 7:16 am

The loss of labor opportunities is definitely a big blow in automating manufacturing through technology. I’ve seen factories that went from 100 employees in the line to none because of their no-human-touch policy. Technology is good and is helpful to human lives but one way or another, it can be more detrimental to us.

Thomas

August 15, 2018 at 5:42 pm

We can all agree that there are pros and cons when it comes to technology and automation but I believe the pros outweigh the cons. Automation makes life so much easier and it’s the future whether you like it or not. Manufacturing companies should start adopting sooner than later.

Pingback: The Role of Technology in Manufactures – My Study Blog