With overall military spending projected to increase by billions of dollars in the next decade, manufacturers in the aerospace and defense industries have great reason to feel optimistic. An increased demand for aircraft, missiles, and naval craft is buoying spirits across the industry. However, with growing demand and more contracts will come increased scrutiny — officials in Washington have already said so.

Efficiency will be the name of the game. To meet expectations and keep future contracts coming, organizations must rely on technology to improve visibility and flow across supply chains to reduce delays and make better-informed decisions more quickly.

Let’s take a look at how A&D manufacturers can harness chain visibility to maximize the efficiency of their operations.

Improve Supply Chain Visibility and Flow

Well-established A&D manufacturers have had years to develop good relationships with reliable suppliers and buyers. But knowledge of the supply chain can’t end there. Some 40 percent of manufacturers have no visibility into the real-time status of a product’s production status, according to a Smart Manufacturing Technologies survey. Without this insight, it’s impossible to look forward — only backwards.

Common supply chain problems that lead to unwanted product delays include:

- No unified view of orders, invoices, shipments and their respective statuses

- Late orders or shipments

- Mismatched or incomplete orders

- Supply/demand mismatches or misunderstandings

While there will always be bumps in the road, they don’t need to cause headaches and ripple effects across the chain. The beauty of increased supply chain visibility lies in the ability to execute superior planning that minimizes the impact of any delay.

Visibility also gives manufacturers the ability to forecast spikes and drops in demand, preventing stock overflow and back orders. Manufacturers can also track in real-time inventory, raw material, and other necessary supplies.

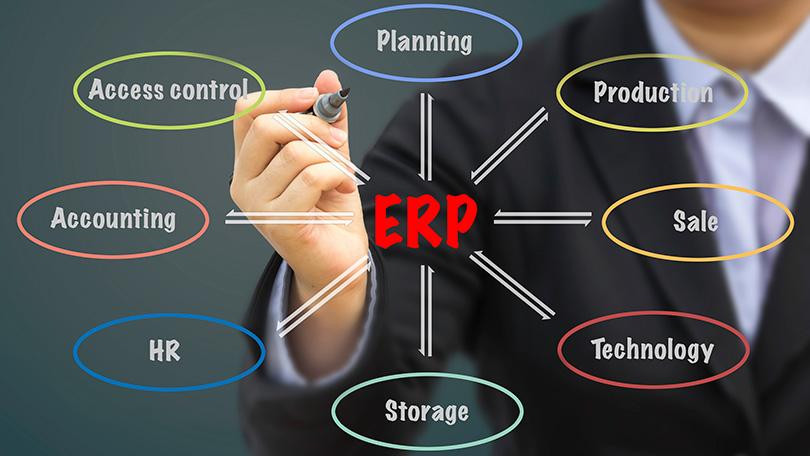

One way to achieve this greater chain visibility is via a strong enterprise resource management (ERP) system fine-tuned to your organization’s operations. Because ERP offers a unified view of product development from sourcing materials to delivery, these systems help to eliminate inefficiencies for A&D manufacturers.

Eliminating common supply chain inefficiencies can have a tangible effect on profits and delivery windows. In the competitive arena of military contact bidding, those who have figured out how to maximize internal efficiency will have the edge.

Make Better Decisions, Informed By Better Data

Improving visibility across the entire supply chain will put decision-makers in a much better position to make data-driven decisions. Having a bird’s-eye view of the supply chain offers context; it will allow executives and managers to see both what has brought them to this point and what impact their decision will have further down the chain of production.

With improved supply chain visibility comes improved data visibility. ERP offers a view not only across the supply chain; it allows oversight of all aspects of the process, from invoicing to customer feedback to machine efficiency. How can you maximize efficiency if you don’t know how efficient your machines are at any given time?

Other benefits of improved data visibility include the ability to:

- Plan for the unexpected: Instead of waiting for parts that don’t arrive on time, greater chain visibility will allow manufacturers to plan ahead and better allot time and resources where they can be best used. Knowledge of delays allows an organization to prepare the subsequent points of the chain.

- Improve planning: With better visibility across the supply chain, an organization can better able plan out orders and consider material scarcity and market prices when ordering parts. Suppliers, meanwhile, can offer insights that may lead a manufacturer to order future parts ahead of time if delays are expected.

- Track orders: Damaged products, wrong parts, or incomplete orders will no longer go unnoticed until they arrive at the next destination.

- Better recordkeeping: Whether for compliance purposes, accounting reconciliation, or any other use, the elimination of manual, paper-and-pen records will save time and prevent mistakes and misunderstandings.

ERP effectively ties the elements of production with the bottom line. This doesn’t mean that cutting costs and boosting profits will be easy. The skills, experience, and intuition of managers and executives will always play a role in that. Better data visibility simply gives them what they need to put that industry knowledge to best use.

Other Efficiency Opportunities in the Air and on the Ground

Suppliers are turning to superior operations management, better data from suppliers, and Zero Defects production, all while understanding that the long-term solution is to interlock all of these systems to increase efficiency.

Other important developments that will influence A&D manufacturing efficiency include:

- Big data: The use of Big Data in production processes can boost productivity while reducing assembly costs by eliminating waste through efficient insights. Sizeable investments in Big Data will lead to predictive maintenance and monitoring to reduce costs and improve the quality of products.

- Internet of Things (IoT): 56% of A&D executives have identified IoT and sensor data as critical to their future, according to a study by PricewaterhouseCoopers, and we expect that figure will continue to rise. Via the IoT, devices can communicate with one another and human operators to create leaner protocols.

- Additive manufacturing: Commonly called 3D printing, AM has seen a surge of investment from the likes of GE, among others. With the speed at which replacement parts can be created via AM, aircraft spend less time on the ground and more time in the air.

Staying Ahead of the Efficiency Curve

Never before has the manufacturing process been so interconnected. The number of tools and strategies that can be harnessed to boost efficiency grows with technology. There have never been so many opportunities available, but with this boon comes the burden of staying on top of developments in all areas of A&D production where these time- and cost-cutting strategies can be found. Given the opportunity the next few years present, there’s no excuse not to do so.

Aaron Continelli, president of Cre8tive Technology and Design, started things small in 2005. What began as a one person consulting firm has now become a staff of 58 with three office locations. Specializing in ERP system sales and services, Cre8tive Technology and Design became an EPICOR Partner (Value Added Reseller) in 2007. Since then, Cre8tive Technology and Design has emerged as one of EPICOR’s ELITE and won the 2013 Americas Partner of the Year as the Top Revenue Producer.