3D designing can get a bit confusing indeed, especially because there’s no particular size or template that’s capable of fitting all approach from the general sense of view.

We use a variety of software, printing materials as well as a number of printing technologies for printing something in 3D. So naturally, one may easily get lost and make a whole lot of mistakes on the way.

In this article, we have highlighted a few of the commonest mistakes that designers make in their 3D designs. Let’s go through them without further ado.

1. Ignorance of material knowledge

Different types of materials are used for 3D printing. A few examples may include things like:

- Ceramic,

- Plastic,

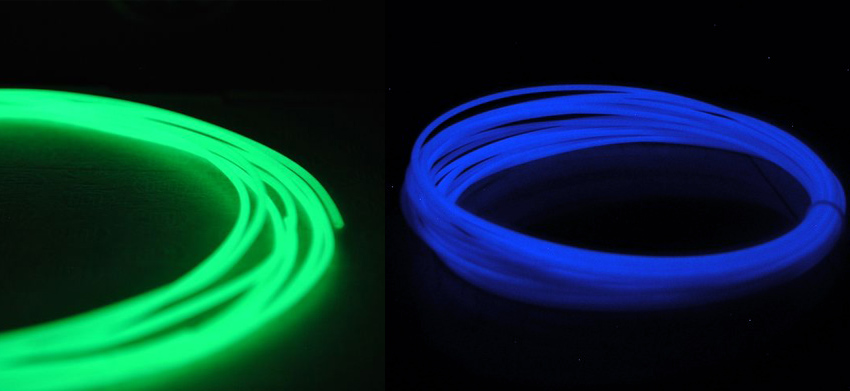

- Rubber,

- Metal (primarily Aluminium and Cobalt),

- Paper,

- Food and

- Organic matter.

Most designers ignore the knowledge of these 3D printing materials in their designs which ultimately leads to a failure. Make sure you don’t do that.

Solution:

You, as a designer MUST be aware of the materials that you are going to use for your print. There’s a specific material-related designing guide that you need to maintain to maximize results in the long run.

2. Ignoring software guidelines

The 3D printing technology uses a host of 3D modeling software for designing purposes.

You, as a 3D designer must be aware of this fact. Some software are designed specifically for 3D prints, whereas some are designed specifically for the artists and the designers. You need to know what to use and when to use based on your requirements.

Solution:

Before using any software, you need to go through its brochure well. You need to be aware of its purpose and potentials. If you think it matches your requirements, go ahead with it.

3. Ignoring 3D printing technology

You can’t use one universal printing technology for printing designs in different materials. Different materials call for different printing technologies and you need to make your decision on the basis of that.

Say for example,

You use technology X for printing out materials in ABS, Alumide, Polyamide, rubber etc. Do you think you can use the same technology for printing out materials in metal?

You can print interlocking parts with materials like ABS and rubber but do you think you can do the same thing while using metals like bronze, gold, resin etc.? You can’t (at least not yet!). Hence, your printing technology needs to differ as a result of your varying requirements.

Solution:

Know your printing tech well. Research a bit on the web or you may also refer to the guidelines that come with it for this purpose of yours. What did you find? Is it suitable for the job? If it is, go ahead without further ado.

4. Not paying much heed to file resolution

So you know your printing materials wells. You have also read the design guides and have made your approach on basis of that. You have selected your software. The only things that are left now are the file resolution and the format.

Many designers ignore the importance of resolution in their designs which leads to problems during the print.

The most common file format used in 3D printing is known as STL (Standard Triangle Language). Many 3D modeling software do provide their users with an option to set their resolutions after the design’s exported to a STL format, but the question is do they really pay much heed to it?

There are a couple of things that you should be aware of about resolutions in 3D designing and printing. If it’s too low, it can create problems by leading to a “pixelated” print. If it’s too high, it may lead to an exceptionally large file size which, in turn may create issues during uploads.

Solution:

There has to be a balance somewhere particularly when the resolution is concerned. This article may come in handy for this purpose of yours.

5. Last but not the least, the ignorance of wall thickness

Wall thickness issues are commonly seen in 3D model designing. If the thickness of the wall is too thin and is way below a certain limit, it’ll be unable to print small parts of the model as per the requirements.

On the other hand, if the thickness of the wall is too thick and is way beyond a designated limit, it may result in the formation of a product that may crack easily on application of pressure.

Solution:

A special tab must be kept on wall thickness and a proper balance needs to be maintained.

Lastly, I would like to repeat that the key to keeping mistakes at bay is to learn from the same with the determination to not repeat them in future. Hope the ones highlighted above come in handy for this exact purpose of yours. Ciao!

Albert Smith is passionate about 3d Design service. He is a freelance architect and a property management consultant in West Palm Beach, Florida. You can find Albert’s articles on many property blogs and article directories. Currently he is writing on the progress of the technology developed by the touch screen company for property and architecture. Albert suggests his readers to follow icreate 3D for additional information on architectural animation.

4 Comments

Leave a Reply

Cancel reply

Leave a Reply

This site uses Akismet to reduce spam. Learn how your comment data is processed.

Hayden Stewart

August 29, 2017 at 8:34 pm

3D Printers are so amazing. This article is an awesome representation of that, thanks for sharing!

Onisifor Ghibu

May 22, 2018 at 5:13 pm

Awesome article. Thank you very much! I usually hire 3d modeling services to make 3d printing models for my purposes. I think it’s better to use professional’s knowledge to achieve the best result! 🙂

Shalmali Bapat

July 30, 2018 at 6:01 am

It is known that in 3d printing technology, no one size fits every approach, So sometimes you might feel lost and it can sometimes appear difficult to make a perfect 3D model for 3D printing. but thanks a lot for telling us which mistakes to avoid while doing it. so thank you so much. Kudos to this article.

Gervase

September 1, 2018 at 8:28 pm

Being ingorant can be combatted. It is all part of the learning curve involved with getting to understand and use a 3D printing machine